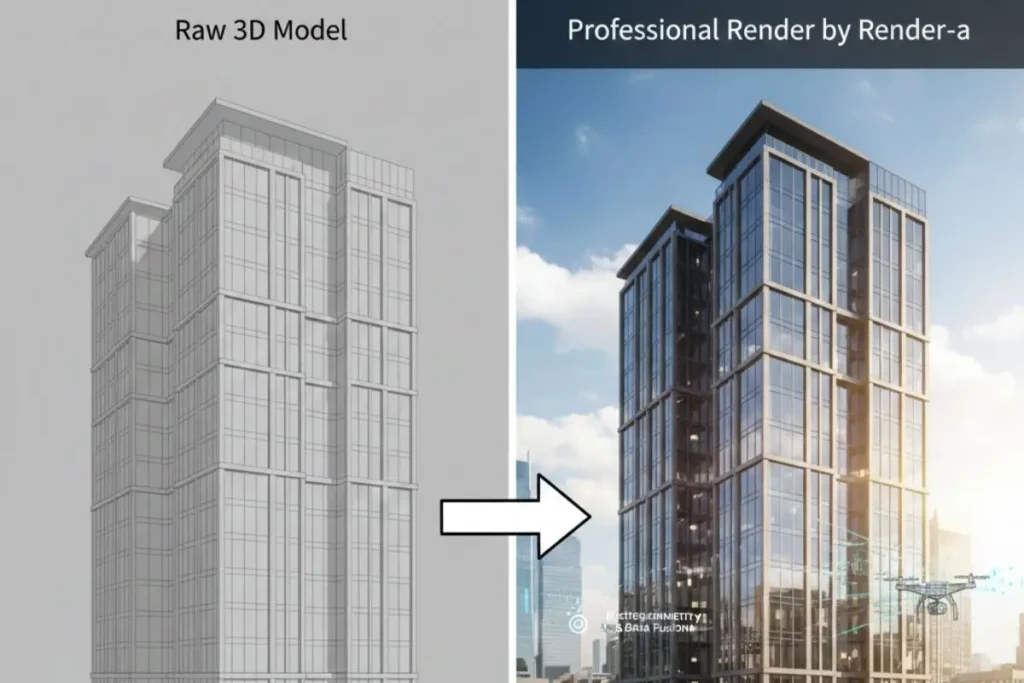

“The difference between a good 3D model and a great one isn’t the geometry. It’s the truth embedded in the data.” This observation from our lead technical team at Render-a captures precisely why so many digital reconstructions fall short of photorealism. The issue isn’t talent or software capability. The problem lies in the foundation itself.

In our years working with architectural firms, engineering consultancies, and construction companies across the United States, we’ve encountered countless frustrations with digital models that look artificial. Clients invest significant resources into creating 3D models, only to discover the final output appears flat, unconvincing, and commercially unusable. The culprit? A fundamental misunderstanding of what creates visual realism in the digital realm.

The Foundation: Why Manual Estimation No Longer Suffices

Traditional 3D modelling workflows rely heavily on manual measurements and estimations. An architect might visit a site, take photographs, record dimensions with a tape measure, and reconstruct the environment back in the studio. This approach worked adequately for decades.

But it introduces critical gaps.

Manual measurement cannot capture the micro-variations in surface topology. A brick wall isn’t perfectly flat. A roof doesn’t sit at exactly 30 degrees across its entire span. These subtle irregularities are precisely what our eyes recognise as authentic. When they’re absent, our brains immediately flag the image as artificial, even if we can’t consciously articulate why.

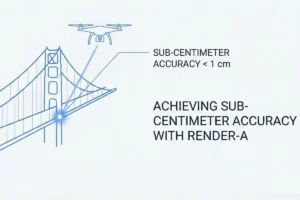

This is where drone measurement fundamentally transforms the data acquisition process. By deploying unmanned aerial systems equipped with precision sensors, we capture spatial information at millimetre-level accuracy across entire structures. A drone roof survey doesn’t just measure the roof’s overall dimensions. It records every undulation, every weathered edge, every slight deviation from geometric perfection.

In our experience with complex site captures, the data density from a professional drone survey provides 100 to 1000 times more spatial information than manual methods. That abundance of accurate data becomes the biological foundation for truly realistic rendering. You cannot fake precision. You can only capture it.

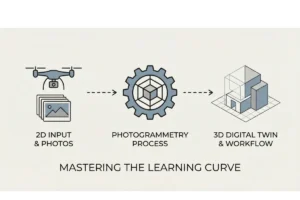

The Texture: How Photogrammetry Captures Surface Truth

Geometry alone doesn’t create realism. A perfectly modelled chair with flat grey surfaces still looks like a training render from 1995. What transforms digital geometry into convincing reality is texture, and more specifically, the accurate representation of how surfaces interact with light.

Photogrammetry solves this challenge through an elegant principle. By capturing hundreds or thousands of overlapping photographs from multiple angles, photogrammetric software reconstructs not just the shape of an object, but also its complete surface characteristics. Every colour variation, every weathering pattern, every reflective quality gets encoded into the digital representation.

The process essentially reverse-engineers reality.

Traditional texture mapping requires artists to photograph surfaces, manually align those images to 3D geometry, and hope the result looks convincing. Photogrammetry eliminates that guesswork. The texture data is inherently aligned with the geometry because both derive from the same source: reality itself.

When combined with precision drone measurement, photogrammetry delivers what we call “truth-mapped models.” These digital assets contain authentic surface information at resolutions that manual processes simply cannot match. A drainage vent isn’t approximated. It’s captured exactly as it exists, with genuine weathering patterns, authentic material reflectance, and real-world imperfections that signal authenticity to the human eye.

Why Raw Data Still Isn’t Enough

Here’s the counterintuitive reality: even with perfect spatial data from drone surveys and authentic surface information from photogrammetry, your 3D model still won’t look real without proper rendering.

Raw photogrammetric outputs are technically accurate but visually crude. The mesh might have millions of polygons, and the textures might contain genuine colour information, but the lighting is baked in from whatever conditions existed during capture. Shadows are permanent. Reflections are fixed. Material properties aren’t physically accurate because the data represents appearance under specific conditions, not the underlying physics of how materials actually behave.

This is where professional rendering expertise becomes indispensable.

The Polish: Advanced Light Physics Applied to High-Precision Data

At Render-a, we treat precision-captured data as raw material for photorealistic visualisation. The drone survey provides geometric truth. The photogrammetry provides surface authenticity. Our rendering pipeline provides the physical light simulation that brings both elements together into convincing reality.

This involves several sophisticated processes that most organisations lack the technical capability to execute internally.

Material Reconstruction

We analyse the photogrammetric textures to separate colour information from lighting information. A brick wall photographed in afternoon sun doesn’t inherently need afternoon lighting baked into its appearance forever. Our technical team reconstructs the underlying material properties: base colour, surface roughness, metallic qualities, translucency, and subsurface scattering characteristics.

These physically-based material definitions allow the surface to respond correctly to any lighting scenario. That same brick wall can now be rendered in morning light, overcast conditions, or artificial illumination, and it will appear authentic in every context.

Global Illumination and Ray Tracing

Real light bounces. A red wall casts subtle red tones onto adjacent white surfaces. Sky light filters through leaves differently than it penetrates glass. These infinitely complex interactions are what make reality look real.

Professional rendering engines simulate these phenomena through ray tracing and global illumination algorithms. Each pixel isn’t just coloured based on direct light. It accounts for indirect illumination bouncing from surrounding geometry, atmospheric scattering, caustic patterns from reflective surfaces, and the subtle colour bleeding that occurs between adjacent materials.

We apply these advanced rendering techniques specifically to models built from drone measurement and photogrammetry data. The precision geometry ensures that light interactions calculate correctly. Inaccurate geometry creates incorrect shadows, wrong reflections, and ultimately, visual artificiality.

Environmental Integration

A perfectly rendered building floating in a void still looks wrong. Professional visualisation requires environmental context: accurate sky models, atmospheric haze appropriate to viewing distance, ground-level vegetation that matches the geographic region, and atmospheric perspective that makes distant objects appear correctly faded.

These elements complete the illusion of reality. In our production workflow, we combine the precision data from drone surveys with environmental augmentation that places the subject within a believable context. The technical accuracy of the measured geometry provides credibility, while the environmental integration provides the holistic realism that resonates emotionally with viewers.

Key Takeaways

- Precision data is fundamental. Manual measurements lack the density and accuracy required for photorealistic rendering.

- Drone measurement captures geometric truth. Millimetre-level accuracy across entire structures eliminates the approximations that signal artificiality.

- Photogrammetry provides authentic surface characteristics. Real-world texture data beats manually created materials every time.

- Raw data requires professional rendering. Accurate geometry and textures aren’t enough without proper material reconstruction and light physics simulation.

- Integration matters. Precision models need environmental context and atmospheric effects to achieve complete realism.

- Expertise transforms data into deliverables. The technical capability to process drone survey data, reconstruct materials, and apply advanced rendering separates amateur outputs from professional results.

The Render-a Difference

What sets our approach apart isn’t just access to advanced technology. Many organisations own drones and photogrammetry software. The differentiator is the integrated expertise to transform raw spatial data into commercially valuable visual assets.

Our technical team understands the complete pipeline from data acquisition through final pixel output. We know which drone sensors provide optimal accuracy for specific applications. We understand the photogrammetric processing parameters that balance detail against computational efficiency. We possess the rendering expertise to reconstruct physically accurate materials from real-world captures.

This comprehensive capability means clients receive finished deliverables, not raw data files requiring additional expertise to utilise. A drone roof survey conducted by Render-a doesn’t just produce a point cloud. It results in a photorealistic 3D model ready for architectural presentations, insurance documentation, facility management integration, or marketing visualisation.

The data we capture has inherent value. The visualisations we deliver have commercial impact.

Learn more about our approach through our LinkedIn company page or explore project examples on our YouTube channel.

Frequently Asked Questions

Why do manually created 3D models look less realistic than photogrammetry-based models?

Manually created models rely on approximation and artistic interpretation. Even skilled modellers cannot replicate the micro-variations in surface topology and authentic weathering patterns that exist in real structures. Photogrammetry captures these subtle irregularities directly from reality, providing a level of geometric and textural detail that manual processes cannot match. The human eye recognises these authentic imperfections as real, while geometric perfection reads as artificial.

How does drone measurement improve 3D model accuracy compared to traditional surveying?

Drone measurement systems capture hundreds or thousands of data points across entire structures in minutes, achieving millimetre-level accuracy across large areas. Traditional surveying with tape measures and laser distance finders can only record specific measurement points, requiring interpolation between those points. Drones equipped with precision sensors document complete surface topology, capturing undulations, deviations, and structural irregularities that manual methods miss entirely. This data density is essential for photorealistic rendering.

What is the difference between a basic 3D model and a professionally rendered model?

A basic 3D model contains geometry and perhaps simple colour information, but lacks physically accurate material properties and sophisticated lighting simulation. Professional rendering involves material reconstruction to separate base colour from lighting effects, ray-traced light simulation that accounts for indirect illumination and atmospheric effects, and environmental integration that places the subject in believable context. The geometry might be identical, but the rendering quality determines whether the final image appears artificial or photorealistic.

Can I create photorealistic visualisations without using drone survey data?

While skilled artists can create convincing visualisations through manual modelling and texturing, achieving photorealism for existing structures or complex sites without precision data capture is extraordinarily difficult and time-consuming. Drone surveys and photogrammetry provide the geometric accuracy and authentic surface detail that form the foundation for photorealistic rendering. Manual approaches require extensive artistic interpretation and often result in subtle inaccuracies that undermine realism. For documentation of existing conditions, precision data capture is effectively mandatory for professional results.

Conclusion

The gap between acceptable 3D visualisation and truly photorealistic rendering isn’t software capability or artistic skill. It’s data quality and technical expertise in processing that data.

Precision measurement through drone surveys provides geometric accuracy. Photogrammetry captures authentic surface characteristics. Professional rendering expertise transforms both into commercially valuable visual assets that withstand scrutiny and drive business outcomes.

Organisations attempting to handle this pipeline internally often discover that owning the tools doesn’t equate to possessing the expertise. Data processing, material reconstruction, and advanced rendering each require specialised knowledge that takes years to develop.

Render-a exists to bridge that gap. We combine data acquisition expertise, processing capability, and rendering specialisation into a comprehensive service that delivers finished photorealistic models from initial site survey through final pixel output.

If your current 3D models lack the realism your projects demand, the solution isn’t better software or more talented artists. The solution is better data and the expertise to transform that data into visual truth. That’s precisely what professional rendering provides.