The difference between a good 3D model and a great one isn’t the geometry. It’s the truth embedded in the data. This observation from our lead technical team at Render-a captures precisely why so many digital reconstructions fall short of photorealism. The issue isn’t talent or software capability. The problem lies in the foundation itself.

In our years working with architectural firms, engineering consultancies, and construction companies across the United States, we’ve encountered countless frustrations with digital models that look artificial. Clients invest significant resources into creating 3D models, only to discover the final output appears flat, unconvincing, and commercially unusable. The culprit? A fundamental misunderstanding of what creates visual realism in the digital realm.

The Ladder Liability: The Hidden Costs of Manual Solar Site Surveys

For solar panel installation, the traditional method of roof measurement is a relic of the past, fraught with hidden dangers and inefficiencies. Picture this: a team member scaling a ladder, tape measure in hand, meticulously documenting every dimension and obstruction on a potentially steep or fragile rooftop. This isn’t just a slow process; it’s an occupational safety nightmare.

The risks are undeniable:

- Fall Hazards: According to OSHA, falls are among the leading causes of fatalities in construction. A single misstep can lead to severe injury, or worse.

- Insurance & Liability: Every hour spent on a roof by personnel dramatically increases a company’s insurance premiums and liability exposure.

- Human Error: Manual measurements are susceptible to fatigue, misreading, and environmental factors, leading to inaccuracies that can cascade into costly design flaws and installation delays.

- Time Consumption: A typical roof survey can easily take 2 hours or more, tying up valuable personnel who could be focusing on other aspects of the solar panel installation project.

In our experience at Render-a, the true cost of manual measurement extends far beyond labor hours. It includes the implicit cost of delayed projects, rework due to errors, and the unquantifiable stress of risking human life for data that can now be captured far more safely and effectively.

The 5-Minute Revolution: Autonomous Drone Measurement for Solar

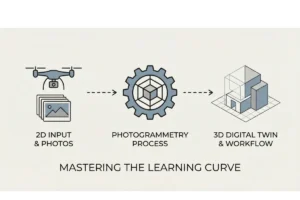

This is where photogrammetry for solar fundamentally changes the game. Imagine replacing that precarious ladder climb with an autonomous drone flight lasting mere minutes. A professional drone, equipped with high-resolution cameras and advanced sensors, performs a drone survey over the target roof, capturing hundreds, even thousands, of overlapping images.

This isn’t just photography; it’s aerial data acquisition. The drone precisely maps every square inch of the roof, documenting its exact dimensions, intricate topology, existing structures (HVAC units, vents), and potential shading elements from surrounding buildings or trees.

Why is photogrammetry for solar the safest measurement method? Photogrammetry for solar eliminates the need for manual labor on high-pitched roofs by using autonomous drones to capture spatial data. This method ensures 100% occupational safety while providing millimetric accuracy for 3D modeling and solar panel placement in a fraction of the time.

The benefits are immediate and profound:

- 100% Safety: No personnel on the roof means zero risk of falls or accidents.

- Unmatched Speed: A comprehensive roof measurement that once took hours is now completed in 5-10 minutes.

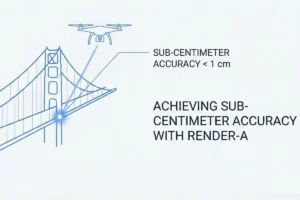

- Unrivalled Accuracy: The data collected is geometrically precise, capturing millimetric details that manual methods simply cannot. This precision is vital for accurate shading analysis and optimal panel placement.

From Raw Data to Digital Twin: Render-a’s 2-Hour Processing Promise

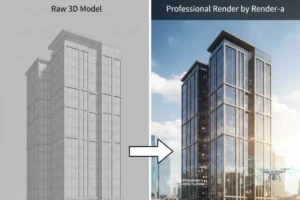

Capturing the raw data is only half the battle. Transforming that massive dataset into a usable, intelligent 3D model is where specialized expertise becomes critical. Many firms acquire drones but quickly realize that processing gigabytes of aerial imagery into a coherent digital twin is a time-consuming and computationally intensive task.

This is where Render-a bridges the gap. We specialize in rapidly converting raw drone measurement data into high-fidelity, actionable digital twin models. Our proprietary pipeline leverages advanced photogrammetry algorithms and cloud-based processing power to deliver results with unprecedented speed.

How long does it take to get an accurate 3D roof model for solar installation? With Render-a, you can receive a fully processed, millimetric-accurate 3D digital twin of your roof, ready for solar panel installation planning, within 2 hours of data capture. This rapid project turnaround time is a game-changer for solar site assessment and overall project efficiency.

Our process involves:

- Orthomosaic & Point Cloud Generation: Creating a perfectly stitched, georeferenced aerial map and a dense cloud of 3D data points.

- 3D Mesh Reconstruction: Transforming the point cloud into a detailed 3D model with accurate roof topology.

- Shading Analysis & Optimization: Providing critical data for determining optimal panel placement and maximizing energy yield.

- Final Deliverable: A ready-to-use digital twin that integrates seamlessly into your solar design software, eliminating the need for internal data processing.

The ROI of Digital Twins: Maximizing Solar Engineering Efficiency

The investment in photogrammetry for solar and Render-a’s processing expertise yields significant returns:

- Error Reduction: Millimetric accuracy means fewer design flaws, less material waste, and reduced rework during installation.

- Accelerated Project Lifecycles: Rapid data capture and processing allow for quicker proposals, faster design iterations, and earlier installation commencements.

- Enhanced Client Presentations: High-fidelity 3D models provide compelling visualizations for clients, demonstrating the proposed solar layout with unparalleled realism.

- Improved Occupational Safety: The single most important ROI is protecting your most valuable asset your team.

The Render-a Advantage: Beyond Data Capture

What sets our approach apart isn’t just access to advanced drone technology. Many organizations own drones and photogrammetry software. The differentiator is the integrated expertise to transform raw spatial data into commercially valuable visual assets.

Our technical team understands the complete pipeline from drone survey acquisition through final 3D modeling output. We know which drone sensors provide optimal accuracy for specific solar panel installation applications. We understand the photogrammetry processing parameters that balance detail against computational efficiency. We possess the geospatial precision expertise to reconstruct physically accurate roof topology from real-world captures.

This comprehensive capability means clients receive finished deliverables, not raw data files requiring additional expertise to utilize. A drone roof inspection conducted by Render-a doesn’t just produce a point cloud. It results in a photorealistic 3D model ready for solar engineering efficiency, architectural presentations, insurance documentation, or marketing visualization.

The data we capture has inherent value. The visualisations we deliver have commercial impact.

Protect your team’s safety and propel your projects forward. Don’t risk another manual measurement. Transition to 3D digital twin technology with Render-a today.

Ready to eliminate the risks of manual measurement and scale your solar operations? Explore how our specialized services can transform your workflow:

- Optimize Your Workflow: Discover our full range of 3D modeling solutions designed for precision and speed.

- Safety First: Schedule a professional drone roof survey to capture millimetric data without ever leaving the ground.

- See the Results: Watch our technology in action and explore project showcases on our YouTube channel.

- Stay Informed: Follow our latest industry insights and technical updates on LinkedIn.

Don’t just capture data create visual truth. Contact Render-a today to start your transition to high-fidelity 3D digital twins.

Frequequently Asked Questions

How accurate is photogrammetry for solar roof measurements? Photogrammetry for solar, especially when conducted with professional-grade drones and processed by experts like Render-a, can achieve millimetric-level accuracy. This precision far exceeds traditional manual measurement methods, providing highly reliable data essential for optimal solar panel placement and design.

What are the main safety benefits of using drones for solar surveys? The primary safety benefit is the complete elimination of personnel needing to physically access dangerous rooftops. This drastically reduces the risk of falls, injuries, and heat-related illnesses, ensuring 100% occupational safety during the data acquisition phase.

Can photogrammetry help with shading analysis for solar installations? Absolutely. The high-precision 3D digital twin created through photogrammetry accurately maps all roof obstructions and surrounding structures. This detailed 3D model allows for highly accurate shading analysis, crucial for maximizing the energy output of solar panels throughout the day and year.

How quickly can Render-a provide a usable 3D model from a drone survey for solar? Render-a prides itself on rapid project turnaround. We can typically process raw drone survey data into a complete, usable, and millimetric-accurate 3D digital twin for solar panel installation planning within 2 hours of data capture, allowing for immediate design and assessment.