“The roof is the fifth wall of a building,” noted renowned architect Frank Lloyd Wright, emphasizing that what protects us from the elements deserves the same careful attention as any structural component. Today, the way we inspect roofs has undergone a dramatic transformation. What once required workers scaling ladders and scaffolding has evolved into a data-driven discipline where drones and advanced analytics provide unprecedented insights into roof condition. This comprehensive guide examines how modern roof inspection methods are revolutionizing the industry while comparing their efficiency and costs against traditional approaches.

Understanding the Importance of Roof Inspection

A roof inspection serves as a critical preventive maintenance tool that identifies damage, deterioration, and potential failures before they become costly problems. Regular roof inspections can extend the lifespan of your roofing system, maintain property value, and ensure the safety of occupants. However, the method by which you conduct these inspections significantly impacts not only the quality of data you receive but also the safety of personnel and your operational costs.

The roof inspection industry has traditionally relied on manual methods that involve physical access to the roof, often under challenging weather conditions and significant safety risks. Today, technological advances have introduced automated solutions that capture more data, process information faster, and do so with minimal human risk.

Traditional Roof Inspection Methods: Process and Limitations

How Traditional Inspections Are Conducted

Traditional roof inspection methods typically involve the following steps:

- Safety equipment setup including harnesses, ropes, and fall protection systems

- Scaffolding or ladder installation

- Physical walkthrough of the roof surface

- Manual documentation using cameras and notes

- Post-inspection report compilation and analysis

These inspections require trained personnel to physically access the roof, examine every section, and document their findings. While this approach provides direct visual assessment, it carries substantial limitations.

Safety Risks and Hidden Costs

According to the Occupational Safety and Health Administration (OSHA), falls remain one of the leading causes of serious injuries and fatalities in the construction industry. Workers conducting traditional roof inspections face exposure to:

- Fall hazards from heights

- Weather related exposures including extreme temperatures and precipitation

- Unstable or deteriorated roofing surfaces

- Fatigue from physical exertion on uneven terrain

- Limited visibility in certain roof sections or under adverse conditions

Beyond safety concerns, traditional inspections involve substantial hidden costs. Scaffolding fees typically range from €6 to €12 per square meter, translating to thousands of dollars for even modest commercial properties. Equipment rental, labor hours, insurance premiums for high-risk work, and travel time for specialized personnel all accumulate quickly.

The time investment is considerable as well. A traditional inspection of a 10,000 square foot commercial roof can require 2 to 3 days of labor, with weather delays frequently extending timelines further. Property owners must also coordinate access, potentially disrupting building operations during business hours.

Modern Drone-Based Roof Inspection Technology

How Drone Inspections Work

Drone-based roof inspections represent a fundamental shift in how professionals assess roofing condition. These inspections employ unmanned aerial vehicles equipped with high-resolution cameras, thermal imaging sensors, and specialized software to capture comprehensive data about roof surfaces without requiring personnel to physically access the roof.

The process typically involves:

- Pre-flight planning and site assessment

- Autonomous or manually guided drone flight over the roof structure

- Real-time capture of high-resolution imagery and thermal data

- Generation of orthomosaic maps and 3D point clouds

- Advanced data processing and analysis

- Delivery of actionable insights and visualizations

Efficiency Gains and Speed Advantages

The efficiency improvements delivered by drone inspections are substantial. Studies demonstrate that drone-based workflows complete inspections approximately 90% faster than traditional methods. A roof that would require 2 to 3 days of manual inspection can be thoroughly assessed by drone in 30 to 60 minutes, including flight time, data capture, and initial processing.

This dramatic acceleration in workflow doesn’t compromise data quality. In fact, drones capture significantly more data points than human inspectors could possibly assess during a ground-based visit. High-resolution cameras with 20-megapixel sensors can identify defects as small as a few millimeters from safe flying altitudes.

The Intelligence Layer: Data Processing and 3D Visualization

Beyond Raw Aerial Imagery

While drone capture capabilities are impressive, the true value of modern roof inspection lies not simply in the flight itself, but in sophisticated data processing that converts raw aerial imagery into structured, actionable maintenance insights. This distinction represents the critical difference between a roof inspection service and a comprehensive intelligence platform.

After data capture, the imagery undergoes several processing steps that transform it from raw pixel data into meaningful information:

- Orthomosaic processing to create geometrically accurate, seamless roof maps

- 3D point cloud generation for precise measurements and volumetric analysis

- Thermal image analysis to identify insulation deficiencies and moisture infiltration

- Damage detection and classification using advanced algorithms

- Integration with building information models and historical inspection data

- Automated report generation with prioritized maintenance recommendations

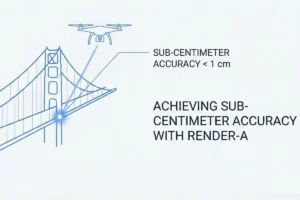

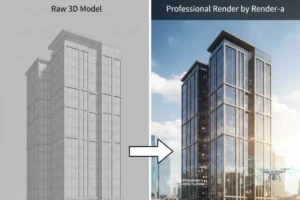

Render-a specializes in this critical intelligence layer, positioning itself as an indispensable partner in roof inspection workflows. By converting drone-captured aerial imagery into sophisticated 3D visualizations and structured data, Render-a enables facility managers, property owners, and contractors to make data-driven maintenance decisions with confidence.

The platform transforms unstructured visual data into georeferenced information systems where every defect, measurement, and observation is precisely located, documented, and actionable. This structured approach to data management enables seamless integration with existing asset management systems and facilitates performance tracking over time.

Comprehensive Cost Comparison: Traditional vs. Modern Methods

Detailed Cost Breakdown

Understanding the true cost differential between traditional and modern inspection methods requires examining multiple cost categories:

| Cost Category | Traditional Inspection | Drone-Based Inspection |

|---|---|---|

| Scaffolding and Equipment | €6-12/m² (€600-12,000 for 1,000 m² roof) | Minimal equipment costs (already owned) |

| Labor Hours | 2-3 days at €50-75/hour = €800-1,800 | 2-4 hours at €35-50/hour = €70-200 |

| Insurance and Permits | $500-1,500 per inspection | $100-300 per inspection |

| Travel Time | 2-8 hours depending on location | 0.5-2 hours |

| Data Processing | Minimal (manual documentation) | Advanced processing (high value) |

| Report Delivery | Basic written report (3-5 days) | Comprehensive with 3D visuals (24 hours) |

Real-World Cost Impact

For a typical 5,000 square foot commercial roof inspection, the cost differential becomes evident. A traditional inspection might total $2,500 to $5,000 when accounting for all direct and indirect costs. The same roof inspected using modern drone methodology would cost $400 to $800, representing a 60 to 85 percent cost reduction.

Beyond the immediate inspection costs, consider the operational impact. Traditional inspections often require scheduling during off-hours or when buildings are closed to ensure worker safety. This limitation disrupts business operations or requires evening/weekend work. Drone inspections face no such constraints, improving operational efficiency and scheduling flexibility.

Safety Advantages of Modern Roof Inspection

Eliminating Worker Risk

Perhaps the most compelling argument for transitioning from traditional to modern roof inspection methods lies in worker safety. Drone-based inspections eliminate the need for personnel to access roof surfaces at height, directly addressing one of construction’s most serious safety challenges.

The safety benefits extend beyond fall prevention. Workers no longer face exposure to:

- Structural hazards from deteriorated roofing materials

- Environmental hazards including extreme temperatures and weather

- Repetitive strain injuries from climbing and walking on uneven surfaces

- Fatigue related incidents from prolonged physical exertion

- Slip and fall hazards on wet or icy surfaces

By eliminating the need for physical roof access, drone inspections achieve what safety professionals call a hierarchy of control solution: engineering out the hazard entirely rather than attempting to manage risk through personal protective equipment or administrative procedures.

Future Trends in Roof Inspection Technology

Artificial Intelligence and Predictive Maintenance

The roof inspection industry continues to evolve rapidly. Emerging technologies promise even greater capabilities:

Artificial Intelligence and Machine Learning: Advanced algorithms can now analyze thermal imagery and visual data to predict failures before they occur, moving the industry from reactive repair to truly predictive maintenance.

Integrated IoT Systems: Permanent sensors installed on roofs can continuously monitor conditions, with drones conducting periodic visual verification and validation of sensor data.

Automated Reporting: Natural language processing converts technical data into clear, stakeholder-friendly reports that clearly communicate findings and recommendations to diverse audiences.

Blockchain Documentation: Inspection records can be securely documented and verified, creating immutable audit trails valuable for insurance claims and property transactions.

Choosing the Right Roof Inspection Partner

Critical Selection Criteria

When selecting a roof inspection service, facility managers should evaluate providers based on several key criteria:

- Pilot certification and regulatory compliance

- Equipment specifications and sensor capabilities

- Data processing capabilities and analysis depth

- Report quality and delivery timeline

- Insurance coverage and liability protection

- Experience with your specific roof type and building classification

- Integration capabilities with existing asset management systems

Providers like Render-a that combine drone capture with advanced data processing and 3D visualization capabilities offer particular value. This integrated approach ensures that the intelligence derived from aerial inspection is maximized and immediately actionable.

For solar installations, property managers should consider specialized partners like Lion Solar who understand the unique inspection requirements of photovoltaic systems integrated with roofing structures.

Frequently Asked Questions About Roof Inspection

How often should roofs be inspected?

Industry standards recommend roof inspections at least once annually, with additional inspections following severe weather events. Properties in harsh climates may require twice-yearly inspections. The lower cost of drone inspections makes more frequent monitoring economically feasible, enabling truly preventive maintenance programs.

Are drone inspections accurate for identifying all roof damage?

Modern drone inspections with high-resolution cameras and thermal imaging detect the vast majority of roof defects visible from above. However, some conditions such as internal membrane separation or structural damage beneath surface layers may require complementary ground-based assessment. Comprehensive inspection programs often employ both methods strategically.

What information do drone inspections provide that traditional methods miss?

Drone inspections capture significantly more visual data through high-resolution orthomosaic maps. Thermal imaging identifies moisture infiltration, insulation gaps, and energy efficiency issues completely invisible to ground-based inspection. 3D point clouds enable precise measurement of surface conditions and volumetric calculations impossible from ground-level assessment.

How is privacy protected during drone roof inspections?

Professional drone operators follow strict privacy protocols, capturing only necessary roof area footage and securing all imagery according to data protection regulations. Flight paths are planned to minimize incidental capture of adjacent properties. Imagery is encrypted, stored securely, and deleted according to client specifications.

Can drone inspections be conducted in all weather conditions?

While drones operate in various weather conditions, strong winds, heavy precipitation, and lightning risk limit operations. Professional operators follow strict weather protocols ensuring safety. Most inspections can be scheduled during favorable conditions within 24-48 hours of request, far faster than traditional inspection scheduling.

What is the typical turnaround time for inspection results?

Initial visual assessment is available immediately following the flight. Comprehensive processed reports with 3D visualizations typically deliver within 24 hours. This rapid turnaround dramatically exceeds traditional inspection timelines, enabling faster decision-making regarding maintenance and repairs.

How much does a drone roof inspection typically cost?

Drone inspection costs vary based on roof size, complexity, and processing requirements. Typically, inspections range from $400 to $2,000 depending on these factors. This represents a fraction of traditional inspection costs, particularly for larger properties where the cost differential becomes most dramatic.

The Modern Path Forward

The evolution from traditional to modern roof inspection methods represents far more than a technological upgrade. It embodies a fundamental shift in how the built environment is maintained and protected. The data is compelling: drone-based inspections deliver 90 percent faster workflows, reduce direct costs by 60 to 85 percent, virtually eliminate worker safety risks, and provide dramatically superior data for informed decision-making.

However, the technology alone tells only part of the story. The true value lies in the intelligence layer that transforms raw aerial imagery into structured, actionable insights. Providers who combine sophisticated drone capture with advanced data processing, 3D visualization, and predictive analysis deliver outcomes that exceed the sum of their parts.

For facility managers, building owners, and property maintenance professionals, the question is no longer whether to adopt modern roof inspection methods, but rather which integrated platform best serves your specific needs. The cost savings alone justify the transition. The improved safety outcomes make it imperative. The superior data quality makes it smart business.

As you consider your roof inspection strategy, evaluate partners who understand that the flight itself is merely the beginning. True value emerges from how raw data is processed, analyzed, visualized, and delivered into your decision-making workflows. This intelligence-driven approach to roof inspection represents the future of building maintenance, and that future is already here.

Learn more about advanced drone-based roof survey solutions by visiting Render-a’s drone roof survey service, or connect with our team on LinkedIn to discuss how modern inspection technology can transform your facility management approach.