In the evolving field of solar development, the margin for profitability and for projects becoming stagnant is determined by one core factor: precision.

The potential for human error and safety issues with in-person surveying are significant and as governing organizations in the UK and Europe are formalizing regulations, the industry is evolving with the UK’s first ‘drone with surveying capabilities’. But speed is not the only consideration: the construction of surveying drones allows organizations to fulfill the requirements for digital surveying with a verifiable and legally compliant digital chain of custody to meet, for example, MCS and DIN certification requirements.

This Renderer-a guide is for the Solar Site Surveying provider in Manchester and the Project Manager in Munich to ensure that their assembled drone data is tailored to achieve the local market incentives and safety compliance.

Why Compliance Matters: MCS vs. DIN

In order to receive financial benefits and gain approval for grid access, your data needs to align with the auditor’s perspective.

UK Market: Securing the MCS Certificate

For UK installers, the Microgeneration Certification Scheme (MCS) is critical for clients in order to get the Smart Export Guarantee (SEG).

The Challenge: MCS has a great focus on the shading factor. Auditors require proof of how surrounding objects (trees, chimneys, nearby dormers) impact the yield.

The Drone Solution: You need 3D Point Clouds that capture the horizon line. A standard 2D map will NOT suffice. By using Render-a to process your drone images, you craft a digital twin that is capable of simulations for shading analyses that meet audit compliance.

European Market: DIN Standards (DIN 18008 & Eurocode)

In Germany and the broader EU, the focus shifts to structural safety and accuracy.

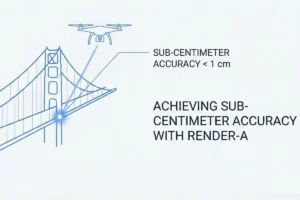

The Challenge: DIN 18008 (Glass in Building) and wind load calculations require certain roof pitch and dimension measurements to be highly accurate. A few centimeters of error can derail your static calculations.

The Drone Solution: High-res photogrammetry achieves sub-centimeter accuracy. This ensures that the mounting systems designed in software like PVSol align with the roof’s actual topography.

Flight Best Practices for Compliance Ready Data

Simply flying your solar site survey will not be enough for auditors and simulation software to accept your site survey data. You must implement a structured flight plan.

Step 1: Optimizing for 3D Modeling

To generate the 3D models that are a necessity for an MCS certificate application:

Overlap is Key: Keep your front and side overlap equal to at least 75-80%. Without strong overlap, photogrammetry software will struggle to stitch images together accurately.

The Double Grid: Fly a cross-hatch or double grid pattern. This way, the camera is able to capture the sides of obstacles (like chimneys) from all angles, preventing the inclusion of blind spots in your shadow analysis.

Step 2: Camera Angles (Nadir vs. Oblique)

Nadir (90°): This is good for 2D maps, but for height analysis, it is not enough.

Oblique (45°-60°): This is essential to capture the height of obstacles. Having a mix of these angles is the best way for Render-a to build a robust Digital Surface Model (DSM).

The Workflow: From Drone to Desktop with Render-a

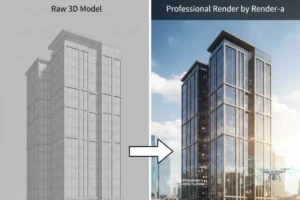

You’ve acquired the data. But how do you turn several gigabytes worth of photographs into a compliant report? Here are the steps in the streamlined workflow:

Uploading to the Cloud: Avoid clogging your local computer. Upload your dataset to Render-a Platform (Internal Link). Our cloud engine is specially designed to handle large photogrammetry datasets.

Generating the Assets: Order an Orthomosaic (for visual assessment) and a 3D Model (.OBJ or .LAS) in case you need to analyze it technically.

Export to CAD/Simulation

For MCS: Upload the 3D model to PVSol or HelioScope. In the 3D environment, conduct the shading analysis. The software will detect the “virtual” trees and the Render-a chimneys, enabling you to obtain a certified yield report.

For DIN: Before you order the mounting kits, check the truss distances and the roof lines in your CAD software to ensure that the DSM is really correct.

Gone are the days of guesswork and manual tape measurements. The current solar market demands efficiency, security, and compliance in solar site survey workflows.

Using drone picture capture and Render-a’s post-processing, you don’t just capture images. You create engineering assets that can accelerate the MCS certification and satisfy all of the strict DIN requirements.

Would you like to improve the accuracy of your surveys? Start your free trial with Render-a to transform your drone data into completed projects.

Official MCS Standards for Solar PV